To guarantee effective overflow trough waterproofing, you should focus on designing proper drainage with adequate slope and outlets to direct water away. Choose durable, weather-resistant materials like membranes or waterproof coatings that bond well and resist environmental factors. Follow installation guidelines carefully, sealing all joints and penetrations to prevent leaks. Regularly inspect and maintain the system, clearing debris and promptly fixing issues. Keep these best practices in mind, and you’ll learn more about achieving reliable waterproofing.

Key Takeaways

- Design the drainage system with proper slope, outlets, and terrain considerations to ensure smooth water flow and prevent buildup.

- Select durable waterproofing membranes compatible with existing structures, resistant to UV, temperature, and chemicals.

- Follow manufacturer guidelines during installation, sealing all joints, edges, and penetrations to prevent leaks.

- Use corrosion-resistant drainage materials and ensure compatibility for long-term waterproofing integrity.

- Perform regular inspections and maintenance to identify issues early and maintain effective waterproofing over time.

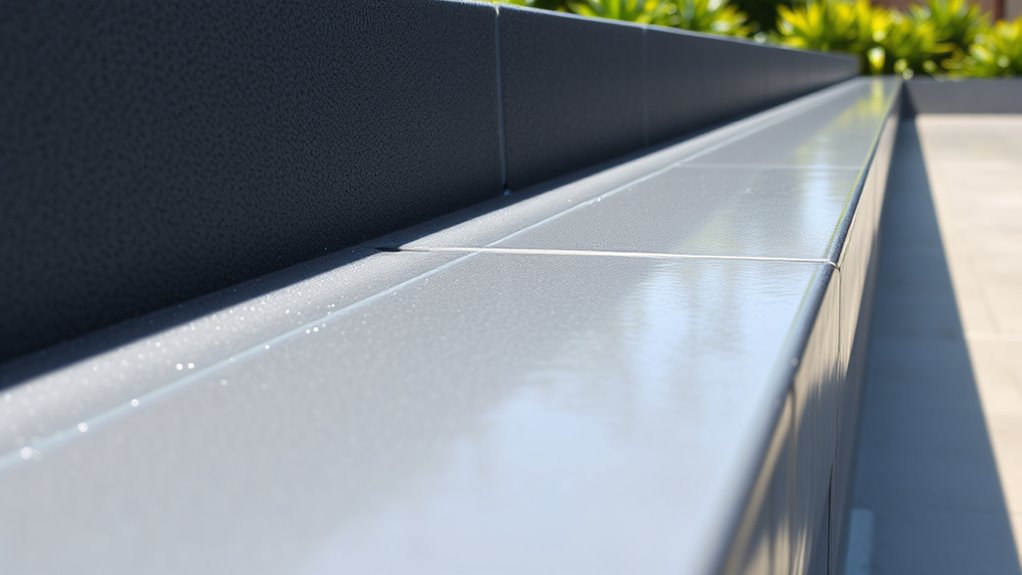

Overflow trough waterproofing is essential to protect your structure from water damage and leaks. When properly waterproofed, the overflow trough can effectively manage excess water, preventing it from seeping into your building’s foundation or causing structural deterioration. A key part of this process involves careful drainage design, which ensures water flows smoothly through the trough and away from vulnerable areas. You need to plan for sufficient slope and appropriate outlets to direct water efficiently, avoiding standing water that can lead to corrosion or leaks. Proper drainage design also involves considering the location of downspouts and the terrain around your building, ensuring water is channeled away from critical zones and that your waterproofing system remains effective over time. Incorporating hydraulic principles into your design helps optimize water flow and prevents buildup.

Effective drainage design is key to waterproofing overflow troughs and preventing water damage.

Material selection plays a vital role in the success of overflow trough waterproofing. You should choose materials that are durable, weather-resistant, and compatible with your existing structure. For the waterproofing membrane, options like bentonite sheets, liquid-applied membranes, or sheet membranes made of EPDM or PVC are popular choices because they provide a reliable barrier against water ingress. When selecting materials, think about their longevity and how well they withstand environmental factors such as UV exposure, temperature fluctuations, and chemical attack. The material should also adhere well to the surface of the trough, creating a seamless seal that prevents water from seeping through joints or gaps.

In addition to the membrane, consider the materials used for the drainage system itself—such as gravel, perforated pipes, or specialized drainage mats—which facilitate quick water movement away from the trough. These materials should be resistant to clogging and corrosion, ensuring long-term functionality. When installing these components, pay close attention to how they interface with your waterproofing membrane to maintain a continuous barrier. Proper sealing around joints, edges, and connections further enhances waterproofing effectiveness, preventing leaks that could compromise your structure.

Finally, always follow manufacturer guidelines and industry best practices when selecting and installing materials. Regular inspections and maintenance are crucial to identify potential issues early, like cracks or deterioration in the waterproofing layer or drainage components. By diligently designing your drainage system and choosing the right materials, you’ll ensure your overflow trough remains effective in safeguarding your building from water damage. Proper waterproofing isn’t a one-time task; it’s an ongoing process that requires attention to detail and proactive care to keep your structure safe and dry for years to come.

Frequently Asked Questions

How Often Should Overflow Trough Waterproofing Be Inspected?

You should inspect overflow trough waterproofing at least twice a year. Regular inspection frequency helps you catch potential issues early, preventing costly repairs. Incorporate these inspections into your maintenance scheduling to ensure waterproofing stays intact and effective. Look for signs of cracks, leaks, or deterioration, and address problems promptly. This routine helps prolong the lifespan of your overflow trough and maintains the overall integrity of your waterproofing system.

What Are Common Causes of Waterproofing Failure?

You often face waterproofing failure due to sealant degradation over time and improper installation. Sealants can break down from UV exposure, temperature changes, or chemical exposure, weakening the waterproof barrier. Improper installation, such as inadequate surface preparation or incorrect application techniques, creates vulnerabilities. Regular inspections help catch these issues early, but understanding these common causes allows you to take preventative steps, ensuring your overflow trough remains waterproof and functional.

Can Waterproofing Be Applied to Existing Overflow Troughs?

Yes, you can waterproof existing overflow troughs. Some maintenance tips include thoroughly cleaning the surface to remove debris and old coatings, then applying effective waterproofing techniques like sealants or membrane coatings. Don’t worry about disrupting your setup; proper preparation guarantees a smooth application. Regular inspections and touch-ups keep the waterproofing intact, preventing leaks and extending the life of your troughs. This proactive approach saves you time and money in the long run.

What Materials Are Best for Overflow Trough Waterproofing?

For overflow trough waterproofing, you should use a high-quality waterproofing membrane that’s compatible with your sealant. EPDM rubber or liquid-applied membranes like polyurethane are excellent choices because they adhere well and provide durable protection. Always check sealant compatibility to guarantee a secure, waterproof seal. These materials resist water intrusion and withstand weathering, making them ideal for preventing leaks and extending your trough’s lifespan.

How Does Climate Affect Waterproofing Longevity?

Climate impact considerably affects waterproofing durability. If you live in a hot, sunny area, UV exposure can degrade protective coatings over time, requiring more frequent maintenance. In cold, wet climates, freeze-thaw cycles may cause cracks, compromising waterproofing. You should select materials suited to your climate, and regularly inspect your overflow trough to guarantee longevity. Properly tailored waterproofing solutions help withstand climate challenges, extending the lifespan of your system.

Conclusion

Now that you know the best practices for overflow trough waterproofing, you’re armed with the secret to preventing floods and disaster. Neglecting these steps could lead to catastrophic water damage that ruins your property and drains your wallet faster than you can blink. By following these simple yet vital tips, you’re fundamentally building a fortress against nature’s fury—because when it comes to waterproofing, a little prevention goes a long, long way. Don’t leave your property vulnerable—protect it with confidence!