To extend your pump and filter lifespan and cut costs, regularly inspect for wear, leaks, and unusual noises. Keep components clean and maintain proper water chemistry to prevent scaling and corrosion. Lubricate moving parts as recommended and replace worn or damaged components promptly. Monitoring system performance helps catch issues early, while maintaining ideal flow and pressure prevents stress on parts. For more tips on keeping your system efficient long-term, continue exploring essential maintenance practices.

Key Takeaways

- Conduct regular inspections to detect wear, leaks, and abnormal noises early, preventing costly repairs.

- Clean filters and components routinely, using proper water chemistry to prevent scaling and corrosion.

- Lubricate moving parts regularly and replace worn components promptly to maintain efficiency and avoid damage.

- Monitor water flow and pressure levels, cleaning valves and filters to ensure unobstructed operation.

- Schedule professional servicing periodically to optimize performance, extend equipment lifespan, and reduce unexpected expenses.

Regular Inspection and Visual Checks

Regular inspection and visual checks are essential for maintaining the ideal performance of your pump and filter system. By routinely examining your equipment, you catch potential issues early before they escalate. Look for signs of wear, leaks, or corrosion, especially around seals and connections. Check the filter housing for cracks or damage, and ensure all fittings are tight. Observe the pump’s operation—listen for unusual noises or vibrations that could indicate trouble. Keep an eye on pressure gauges and flow rates to spot drops or spikes. Regular checks allow you to identify buildup, blockages, or loose parts, helping you address problems promptly. Consistent visual inspections save you money, extend your system’s lifespan, and guarantee it runs smoothly when you need it most.

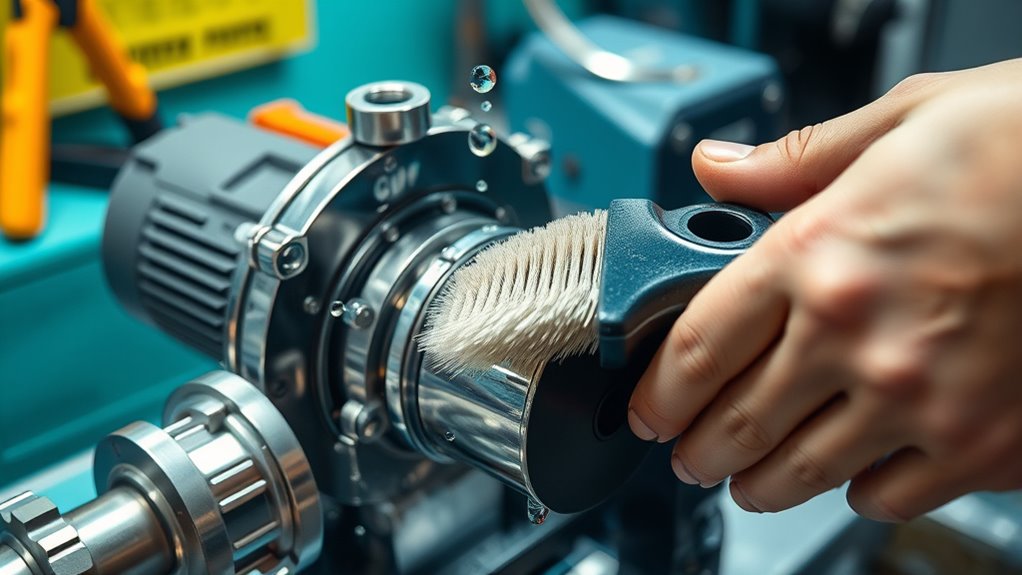

Proper Cleaning Techniques

Ever wondered how proper cleaning can extend the life and efficiency of your pump and filter system? Regular, thorough cleaning removes dirt, debris, and buildup that can clog components and hinder performance. Start by turning off your pump and unplugging it to guarantee safety. Remove the filter cartridge or media and rinse it with a garden hose, avoiding harsh brushes that could damage it. Clean the pump’s intake and impeller housing with a soft brush or cloth to clear any obstructions. Use a mild cleaning solution if needed, but avoid harsh chemicals that could damage parts. Rinse all components thoroughly and reassemble. Consistent cleaning prevents blockages, maintains ideal flow, and reduces the risk of costly repairs, ultimately extending your system’s lifespan. Additionally, understanding family photoshoot fails can remind you to keep your equipment free of surprises and mishaps that could cause delays.

Ensuring Correct Water Chemistry

Maintaining proper water chemistry is essential for your pump and filter’s longevity. You need to regularly check pH levels, add the right chemicals, and prevent buildup that can cause damage. Keeping these in check helps your system run smoothly and lasts longer. Additionally, monitoring water quality is crucial to prevent issues like algae growth or corrosion that can compromise your equipment.

Monitor Ph Levels Regularly

Since water chemistry directly impacts the health of your pump and filter system, it’s essential to monitor pH levels consistently. Regular testing helps you catch imbalances early, preventing corrosion or buildup that could damage your equipment. Use a reliable test kit or digital meter to check pH at least once a week, especially during heavy use or after heavy rain. Keep readings within the recommended range, usually between 7.2 and 7.6, to ensure ideal conditions for your system. If pH levels fall outside this range, take immediate action to correct them. Maintaining proper pH not only protects your pump and filter but also keeps your water safe and clear. Consistent monitoring saves you money by avoiding costly repairs and replacements down the line. Additionally, understanding filtration technologies can help you select the right filters for your needs and ensure optimal performance.

Balance Chemical Additives

After monitoring your pH levels regularly, the next step is to balance chemical additives to keep water chemistry in check. Proper chemical balance prevents damage to your pump and filter system, saving you money and downtime. Here are three key steps:

- Add the right amount of chlorine or sanitizer to keep water clean without over-alkalizing.

- Use algaecides sparingly to prevent algae growth while avoiding chemical imbalance.

- Adjust stabilizers and conditioners to maintain ideal water clarity and prevent corrosion.

Always follow manufacturer instructions for chemical dosages, and test water chemistry frequently. Properly balanced additives support system longevity, improve efficiency, and help avoid costly repairs. Keeping water chemistry in check is essential for smooth, trouble-free operation.

Prevent Scaling and Corrosion

Preventing scaling and corrosion depends on maintaining the right water chemistry. You need to regularly test your water’s pH, alkalinity, and mineral levels to stay within recommended ranges. If the water is too hard, minerals like calcium and magnesium can deposit on surfaces, causing scale buildup that hampers pump efficiency. Conversely, low pH or high acidity accelerates corrosion of metal parts. To prevent these issues, you should adjust chemical levels as needed, using appropriate treatments like pH balancers or corrosion inhibitors. Consistent monitoring and timely adjustments help protect your equipment, extend its lifespan, and reduce costly repairs. Additionally, understanding breakdown of water chemistry can help you better manage water quality for your system. Remember, balanced water chemistry not only prevents damage but also keeps your pump and filter operating smoothly and efficiently over time.

Lubricating Moving Parts

Choosing the right lubricant is key to keeping your pump running smoothly, so be sure to select one recommended by the manufacturer. Establishing a regular maintenance schedule helps you catch potential issues early and keeps moving parts well-oiled. By staying consistent, you’ll extend the life of your equipment and guarantee ideal performance. Incorporating protective styling benefits can also help reduce wear and tear on your pump components.

Proper Lubricant Selection

Selecting the right lubricant is essential for keeping moving parts in your pump and filter system functioning smoothly. Choosing the wrong lubricant can lead to increased wear, overheating, and costly repairs. To guarantee ideal performance, consider these key factors: 1. Compatibility: Use lubricants specifically designed for your pump or filter components to prevent damage. 2. Viscosity: Select a lubricant with the appropriate thickness for your system’s operating temperature and load. 3. Environmental Conditions: Opt for lubricants that resist moisture, dust, and temperature fluctuations common in your setting. Additionally, understanding the performance characteristics of lubricants can help optimize system longevity and efficiency.

Regular Maintenance Schedule

Establishing a regular maintenance schedule for lubricating moving parts keeps your pump and filter systems running smoothly and extends their lifespan. Consistent lubrication reduces friction and prevents wear, guaranteeing *ideal* performance. Check manufacturer recommendations for lubrication intervals and types of lubricants. Keep track of maintenance dates to stay on schedule. If you notice unusual noises or vibrations, lubricate sooner. Use the right lubricant to avoid damage and ensure efficiency. Regularly inspect moving parts for signs of wear or corrosion. Proper maintenance saves you money by preventing costly repairs and downtime. Maintaining proper lubrication practices is essential for optimal operation and longevity of your equipment. Below is a simple schedule to help you stay organized:

| Task | Frequency |

|---|---|

| Inspect moving parts | Monthly |

| Clean lubrication points | Monthly |

| Lubricate moving parts | Every 3 months |

| Check for wear and corrosion | Quarterly |

| Replace damaged parts | As needed |

Monitoring System Performance

To guarantee your pump and filter system runs efficiently, regularly monitoring performance is essential. Keeping an eye on key indicators helps catch issues early and maintain ideal operation. Here are three critical areas to monitor:

- Flow Rate: Ensure water flows smoothly without sudden drops, indicating potential blockages or pump problems.

- Pressure Levels: Maintain proper pressure; fluctuations could signal filter clogging or component wear.

- Noise and Vibration: Unusual sounds or excessive vibrations can point to misalignment or worn parts needing attention.

Replacing Worn or Damaged Components

Regularly monitoring your pump and filter performance helps identify issues early, but addressing problems often requires replacing worn or damaged components. When you notice decreased flow, strange noises, or leaks, inspect parts like impellers, seals, or O-rings. Worn impellers can reduce efficiency and cause vibrations, while damaged seals may leak water and harm internal parts. Always turn off power before replacing components, and use the correct tools for the job. Keep spare parts on hand to minimize downtime. Regularly replacing these components ensures your system operates smoothly, preventing minor issues from escalating into costly repairs. Additionally, employing effective filtration and pump protection measures can prolong equipment life and maintain consistent spray quality. By staying proactive and attentive, you extend the lifespan of your pump and filter, saving money and maintaining peak performance.

Maintaining Optimal Water Flow and Pressure

Maintaining ideal water flow and pressure is essential for your pump and filter system to work efficiently. Proper flow prevents damage, ensures clear water, and extends equipment lifespan. To achieve this, focus on these key aspects:

- Regularly check and clean inlet and outlet valves to prevent blockages.

- Monitor pressure gauges, ensuring pressure stays within recommended ranges.

- Remove debris or buildup from filters to maintain unobstructed water flow.

- Schedule routine inspections and filter replacements based on your system’s total-cost clarity to avoid unexpected repairs.

Scheduling Professional Servicing and Maintenance

Scheduling professional servicing and maintenance guarantees your pump and filter system stays in peak condition. Regular check-ups help identify potential issues before they become costly repairs, ensuring your equipment runs efficiently. When you schedule routine maintenance, technicians can clean, inspect, and replace worn parts, preventing breakdowns and extending the lifespan of your system. It’s essential to follow the manufacturer’s recommended service intervals, especially if your system experiences heavy use or harsh conditions. Advanced Techniques for maintenance can help optimize performance and energy efficiency. Professional servicing also ensures your system meets safety standards and operates at highly effective energy efficiency, saving you money over time. Don’t wait for problems to arise—proactive maintenance keeps your pump and filter system reliable and performing at its best.

Frequently Asked Questions

How Often Should I Perform a Full System Shutdown for Maintenance?

You should perform a full system shutdown for maintenance at least once every six months. Regular shutdowns allow you to thoroughly clean and inspect your pump and filter, preventing buildup and detecting issues early. If your system experiences heavy use or harsh conditions, consider more frequent shutdowns, like quarterly. Always follow your manufacturer’s recommendations for maintenance intervals to guarantee maximum performance and extend the lifespan of your equipment.

What Are the Signs of Impending Pump or Filter Failure?

Did you know that 65% of pump failures are caused by neglecting early warning signs? You should watch for unusual noises, like grinding or squealing, which indicate mechanical issues. Also, if your flow rate drops or there’s inconsistent water pressure, these are signs your pump or filter might be failing soon. Regular inspection helps catch problems early, saving you money and preventing costly breakdowns.

Can DIY Repairs Void My System Warranty?

Yes, DIY repairs can void your system warranty. Manufacturers often require repairs to be performed by authorized technicians to keep the warranty valid. If you attempt repairs yourself and cause damage or use non-approved parts, you risk voiding coverage. To avoid this, always read your warranty terms carefully and consider hiring professionals for repairs, especially if your system is still under warranty.

Which Specialized Tools Are Recommended for Filter Cleaning?

You’ll want a filter brush or a vacuum hose with a brush attachment for cleaning. A garden hose with a spray nozzle helps rinse out debris, while a screwdriver might be needed to open filter compartments. Ironically, the “specialized tools” are often simple household items. Using these tools correctly keeps your filter clean, prolongs its life, and saves you money on replacements—no fancy gadgets required.

How Do Seasonal Changes Affect Pump and Filter Maintenance Needs?

Seasonal changes can substantially impact your pump and filter maintenance. In colder months, you need to winterize your equipment to prevent freezing damage, which involves draining and insulating parts. During warmer months, you might need to clean filters more frequently due to increased debris and algae growth. Adjust your maintenance schedule accordingly, ensuring your pump runs efficiently year-round and avoiding costly repairs or replacements.

Conclusion

By staying proactive with regular inspections and proper maintenance, you can substantially extend your pump and filter’s lifespan while saving money. Some might think it’s too time-consuming, but a little effort now prevents costly repairs later. Imagine enjoying trouble-free operation and peace of mind, knowing your system runs smoothly. Invest a few minutes regularly, and you’ll avoid unexpected breakdowns, ensuring your equipment stays reliable and efficient for years to come.