When designing wind tunnels and baffles for breezy sites, you should analyze local wind patterns, speeds, and directions to replicate real airflow conditions. Selecting durable, lightweight materials like galvanized steel or plastics guarantees longevity and performance. Proper placement and spacing of baffles help redirect airflow and reduce turbulence, while orienting buildings correctly minimizes wind impact. Combining landscape strategies like vegetation further enhances wind management. Keep exploring for detailed insights on creating effective wind control systems tailored to your site.

Key Takeaways

- Conduct site wind analysis to determine prevailing patterns, turbulence, and seasonal variations for accurate wind tunnel modeling.

- Select durable, corrosion-resistant materials like galvanized steel or composites for constructing effective baffles.

- Optimize baffle placement using wind tunnel tests or CFD simulations to control airflow and minimize turbulence.

- Align building orientation with predominant wind directions and incorporate vegetation to naturally reduce wind impact.

- Use flow visualization techniques to refine baffle design, ensuring efficient airflow management on breezy sites.

Understanding Wind Dynamics and Site Assessment

Understanding wind dynamics and conducting thorough site assessments are essential steps in designing effective wind tunnel experiments. You need to analyze local wind patterns, speeds, and directions to predict how airflow interacts with your structure. This involves gathering data on prevailing winds, turbulence levels, and seasonal variations. By comprehending these factors, you can identify potential airflow challenges and optimize your tunnel’s design. Site assessment also includes evaluating surrounding terrain, nearby buildings, and topography, which influence wind behavior. Accurate data ensures your experiments reflect real-world conditions, helping you make informed decisions. Properly understanding wind behavior is crucial for replicating realistic airflow conditions in your tests. Skipping this step risks designing ineffective solutions that don’t account for actual wind forces. Ultimately, a detailed understanding of wind and site conditions forms the foundation for successful wind tunnel testing and architectural resilience.

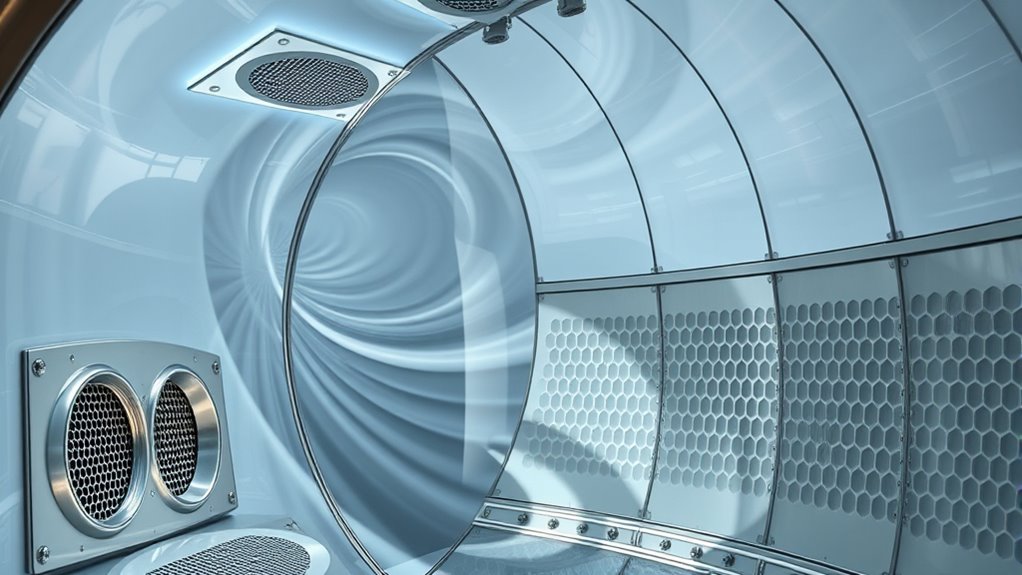

Principles of Wind Tunnel Testing for Architectural Design

Effective wind tunnel testing relies on applying core principles that guarantee accurate simulation of real-world wind conditions. First, you must ensure the scale model accurately represents the full-sized structure, maintaining proportionality in shape and features. Next, you control airflow carefully, adjusting velocity, turbulence, and direction to mimic site-specific wind patterns. It’s essential to measure forces and pressures precisely, using sensors that provide reliable data on how wind interacts with the design. Repeating tests under different conditions helps identify potential issues early. Additionally, you should analyze flow patterns visually through smoke or dye to observe airflow behavior. By adhering to these principles, you can make informed decisions that improve structural resilience, comfort, and overall performance of your architectural project in breezy environments. Incorporating flow visualization techniques can further enhance understanding of airflow dynamics around complex structures.

Materials and Construction of Wind Tunnels and Baffles

When selecting materials for wind tunnels and baffles, you need to consider durability to withstand constant airflow and environmental conditions. Construction techniques and joints are vital for ensuring structural integrity and minimizing airflow disruptions. Additionally, choosing cost-effective materials helps you balance performance with budget constraints, making your project more efficient overall. Using materials with good structural stability is essential to prevent deformation over time and maintain accurate airflow control.

Material Durability and Selection

Selecting the right materials for wind tunnels and baffles is crucial because these structures must withstand constant airflow, pressure fluctuations, and environmental factors without degrading over time. You need materials that resist corrosion, UV damage, and temperature changes, especially if exposed to outdoor conditions. Metals like aluminum and galvanized steel offer strength and corrosion resistance, making them good choices for structural components. For internal surfaces, high-density plastics or coated metals help reduce wear and maintain smooth airflow. Baffles often require lightweight, durable materials like weather-resistant composites. You should also consider ease of maintenance and repair, ensuring the materials won’t become brittle or crack prematurely. Additionally, understanding material properties helps in selecting options that provide optimal durability and performance. Selecting durable, suitable materials guarantees longevity, reduces operational costs, and ensures consistent performance of your wind tunnel or baffle system over time.

Construction Techniques and Joints

Constructing wind tunnels and baffles requires careful selection of techniques and joints to guarantee structural integrity and smooth airflow. You should prioritize strong, weather-resistant joints like bolted or welded connections to ensure stability under wind pressure. Use precise fabrication methods, such as laser cutting or CNC machining, to achieve accurate panel fits. Overlapping joints or flange connections help reduce air leaks and turbulence. Reinforcing critical points with internal braces or gussets adds extra strength without obstructing airflow. When assembling, verify alignment carefully to prevent gaps that could disrupt airflow patterns. Proper sealing around joints with weatherproof sealants maintains airtight integrity. Overall, choosing appropriate techniques and joints enhances the durability and performance of your wind tunnel or baffle system in breezy environments.

Cost-Effective Material Choices

Are cost-effective materials really suitable for building durable wind tunnels and baffles? The answer depends on your goals. Materials like corrugated metal, plywood, and recycled plastics can work well if you choose appropriately and reinforce critical areas. They keep costs low without sacrificing performance when used correctly. Consider the table below to compare options:

| Material | Advantages |

|---|---|

| Corrugated Metal | Durable, weather-resistant |

| Plywood | Easy to work with, inexpensive |

| Recycled Plastics | Lightweight, eco-friendly |

| Foam Boards | Quick assembly, affordable |

While these materials may not last as long as high-end alternatives, they’re practical for temporary or budget-conscious projects. Proper design and maintenance ensure longevity, even with cost-effective choices. Additionally, understanding material durability helps optimize the balance between cost and longevity.

Designing Baffle Systems for Effective Wind Management

To design an effective baffle system, you need to focus on placement strategies that maximize airflow control. Choosing the right materials is vital for durability and performance under varying wind conditions. By carefully considering both points, you can create a baffle setup that efficiently manages wind in your tunnel. Additionally, understanding the impact of airflow patterns can help in optimizing the design for different site conditions.

Baffle Placement Strategies

Effective baffle placement is essential for optimizing wind flow and reducing turbulence around structures or in open spaces. To achieve this, start by analyzing prevailing wind directions and speeds. Position baffles strategically to redirect airflow smoothly, avoiding sharp angles that can cause turbulence. Place baffles upstream of structures to act as shields, or downstream to break up wind currents. Consider spacing baffles appropriately; too close can cause airflow stagnation, while too far apart may be ineffective. Use simulations or wind tunnel testing to refine placement, ensuring wind is redirected efficiently without creating vortices or eddies. Remember, the goal is to create a balanced flow that minimizes wind impact while maintaining natural ventilation. Proper placement enhances safety, comfort, and overall system performance. Incorporating baffle design principles can further improve the effectiveness of your wind management system.

Material Selection Considerations

Choosing the right materials for baffles plays a vital role in guaranteeing wind management systems work efficiently and last over time. You need to take into account durability, resistance to weather, and how the material interacts with wind forces. Materials like galvanized steel, treated wood, or high-density plastics are common choices because they withstand harsh conditions without deteriorating. Flexibility can also be important if you want baffles to absorb some wind energy without breaking. Additionally, select materials that are lightweight yet sturdy enough to maintain their shape and position over time. Cost is another factor; balancing quality with affordability ensures you don’t overspend while still achieving effective wind control. Proper material selection ultimately helps your baffle system perform reliably, reducing maintenance needs and prolonging its lifespan. Using materials with high corrosion resistance can further enhance durability in exposed environments.

Optimizing Building Orientation to Minimize Wind Impact

Optimizing building orientation plays a crucial role in reducing wind impact and enhancing structural stability. By carefully positioning your building relative to prevailing wind directions, you can markedly decrease wind loads. For example, aligning the building’s long axis perpendicular to dominant winds minimizes wind pressure on walls and roofs. Consider local wind patterns and seasonal variations to determine the best orientation. Using wind data, you can identify the most effective angles to reduce turbulence and vortex effects. Proper orientation also improves airflow around the structure, reducing pressure differences that cause damage. Additionally, it can enhance natural ventilation, lowering energy costs. Remember, small adjustments in orientation can lead to substantial benefits in wind mitigation and overall building performance. Incorporating best practices in site analysis ensures an optimal design tailored to specific wind conditions.

Incorporating Vegetation and Landscape Elements for Wind Control

Incorporating vegetation and landscape elements into your site design can markedly influence wind flow around your building. Strategically planted trees, shrubs, and green screens act as natural barriers, reducing wind speed and redirecting airflow away from sensitive areas. Dense planting on the windward side can break up gusts, creating calmer zones near entrances or outdoor seating. Graded terrain and berms help channel wind away from critical zones, while also enhancing privacy and aesthetics. Choose vegetation that’s suited to your climate and growth rate to ensure long-term effectiveness. Proper placement and selection of landscape elements can notably lessen wind pressure, reduce noise, and improve comfort for occupants. Utilizing design principles in landscape planning ensures that wind control methods are integrated effectively and sustainably. This natural approach complements other wind control methods, creating a more comfortable and sustainable site environment.

Analyzing Wind Flow Patterns and Turbulence Reduction

Understanding how wind moves around your site is key to effective wind control. To do this, you need to analyze wind flow patterns carefully. Use tools like wind tunnel testing or computational fluid dynamics (CFD) simulations to observe how air currents interact with your landscape and structures. Look for areas where turbulence increases, causing gusts and unpredictable airflow. Identifying these zones helps you target specific locations for baffles, barriers, or vegetation to reduce turbulence. Pay attention to wind speed, direction, and vortex formation, as these factors influence comfort and safety. By thoroughly analyzing wind patterns, you can design interventions that streamline airflow, minimize turbulence, and create a more stable, breezy environment tailored to your site’s unique characteristics.

Case Studies of Successful Wind Management in Breezy Areas

Many successful projects have demonstrated that strategic wind management can substantially improve comfort and safety in breezy areas. For example, urban developments in coastal cities have used carefully positioned baffles and windbreaks to redirect airflow, reducing gust intensity at pedestrian level. In one case, a university campus installed angled screens that deflect wind around walkways, making outdoor spaces more usable year-round. Similarly, a commercial complex incorporated vertical fins to break up strong wind currents, enhancing outdoor dining comfort. These designs show that understanding local wind patterns and applying targeted mitigation techniques can turn challenging conditions into pleasant environments. By studying these case studies, you can learn how tailored solutions boost safety, reduce wind-related discomfort, and create inviting outdoor spaces even in the breeziest locations.

Future Trends in Wind Simulation and Baffle Technologies

Advancements in wind simulation technology are set to revolutionize how you design and implement baffle systems. With more accurate virtual models, you’ll predict airflow patterns with greater precision, reducing trial-and-error in the field. Future simulations will incorporate real-time data, allowing dynamic adjustments for changing wind conditions. Baffle designs will become smarter, integrating sensors that optimize airflow and minimize turbulence automatically. Enhanced computational methods, like machine learning, will help you identify the most effective configurations faster. As these tools evolve, you’ll create more efficient, cost-effective solutions tailored to specific sites. Overall, these innovations will empower you to better control wind flow, improving energy capture, reducing noise, and protecting structures in breezy environments.

Frequently Asked Questions

How Do Local Climate Variations Influence Wind Tunnel Testing Outcomes?

Local climate variations substantially influence wind tunnel testing outcomes by affecting wind speed, direction, and turbulence levels during tests. You need to take into account these factors to ensure accurate simulation of real-world conditions. When climate changes, your results might differ, so adjusting test parameters becomes essential. By understanding local weather patterns, you can better predict how your structure will respond, leading to more reliable and effective design solutions.

What Are Cost-Effective Alternatives to Traditional Wind Baffles?

You can consider using adjustable or modular baffles as cost-effective alternatives to traditional ones. These options allow you to customize airflow control without investing heavily in permanent structures. Additionally, incorporating simple barriers like sandbags or lightweight panels can help redirect wind efficiently. Using computational modeling to optimize baffle placement also saves money by reducing trial-and-error. These strategies help manage airflow effectively while keeping costs low.

How Can Natural Ventilation Complement Wind Tunnel-Designed Solutions?

Did you know natural ventilation can cut cooling costs by up to 30%? You can complement wind tunnel-designed solutions by strategically placing operable windows, vents, and open spaces to enhance airflow. This way, you optimize the wind’s natural movement, reducing reliance on mechanical systems. You’ll create a comfortable indoor environment while saving energy, making your building more sustainable and cost-effective in breezy sites.

Are There Environmentally Sustainable Materials for Constructing Wind Baffles?

Yes, you can use environmentally sustainable materials for constructing wind baffles. Options include recycled plastic, bamboo, FSC-certified wood, and natural fibers like hemp or jute. These materials reduce environmental impact, are renewable, and often require less energy to produce. By choosing sustainable materials, you help minimize your project’s carbon footprint while ensuring effective wind management on breezy sites.

How Does Urban Development Affect Wind Flow and Baffle Effectiveness?

Imagine embracing the city’s vibrant energy, but know that urban development can subtly disrupt wind flow, making your baffles less effective. Tall buildings and dense structures redirect breezes, creating unpredictable gusts. To maintain ideal performance, you need to account for these changes, perhaps by adjusting baffle placement or design. Staying adaptable helps guarantee your wind control strategies remain efficient, even amid the lively, ever-changing urban environment.

Conclusion

By understanding wind dynamics and using effective baffle designs, you can ensure wind impact on your site is greatly reduced. While some believe natural landscapes alone suffice, studies show that thoughtfully engineered baffle systems outperform greenery in turbulence reduction. Embracing advanced wind tunnel testing and innovative materials ensures your project resists breezy conditions better. So, don’t rely solely on intuition—invest in proven wind management strategies to create safer, more comfortable spaces.